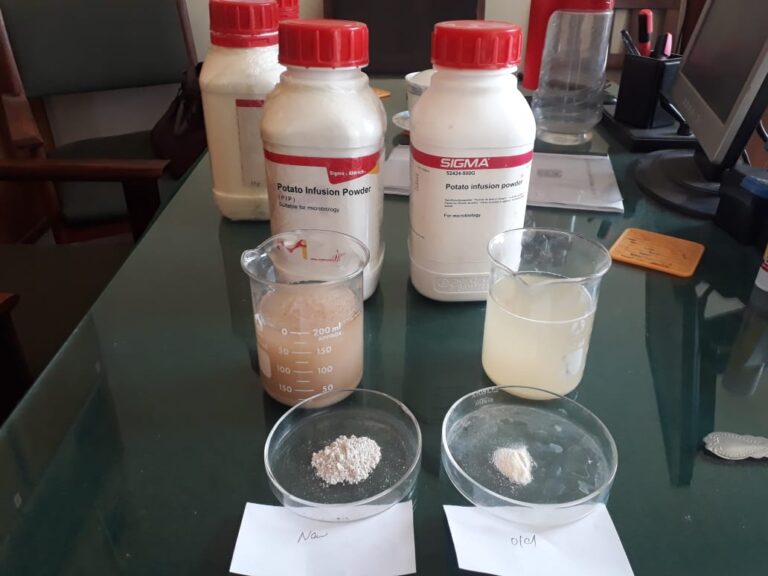

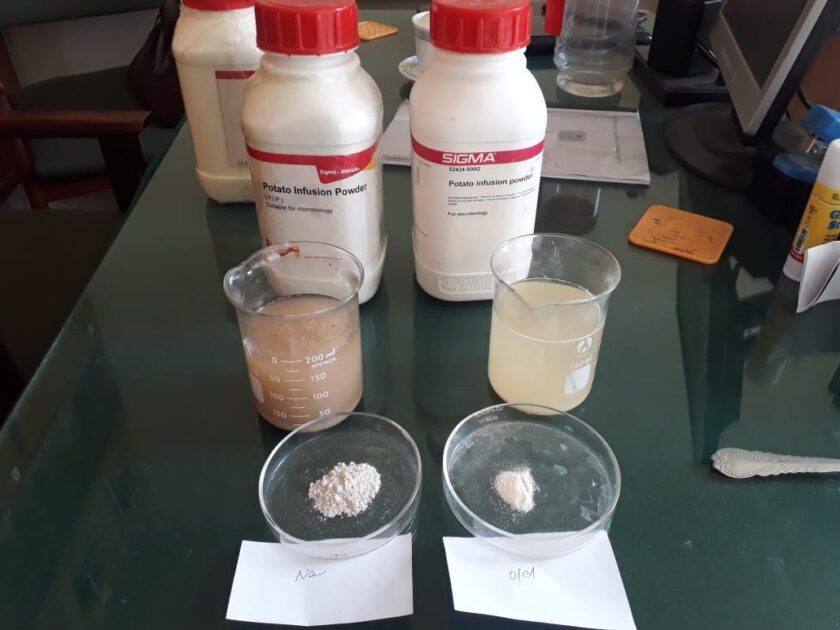

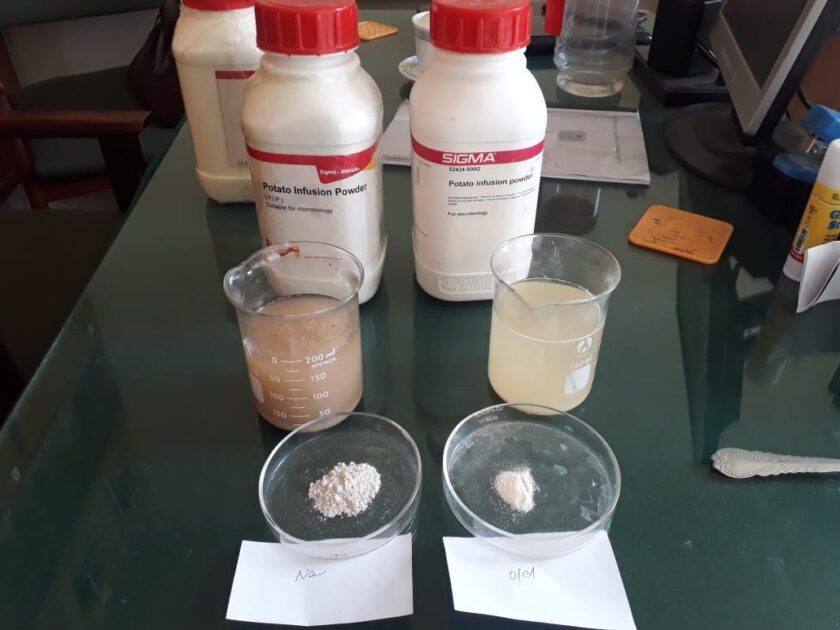

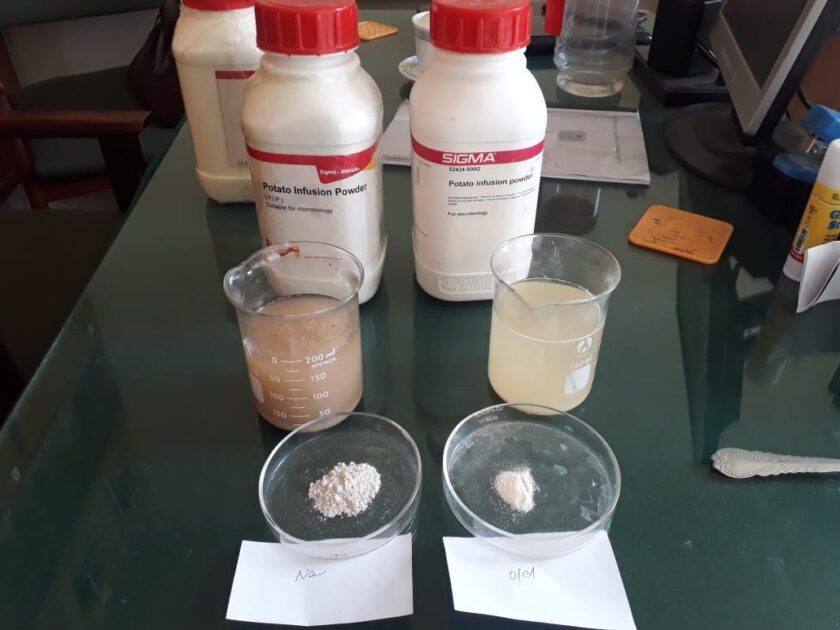

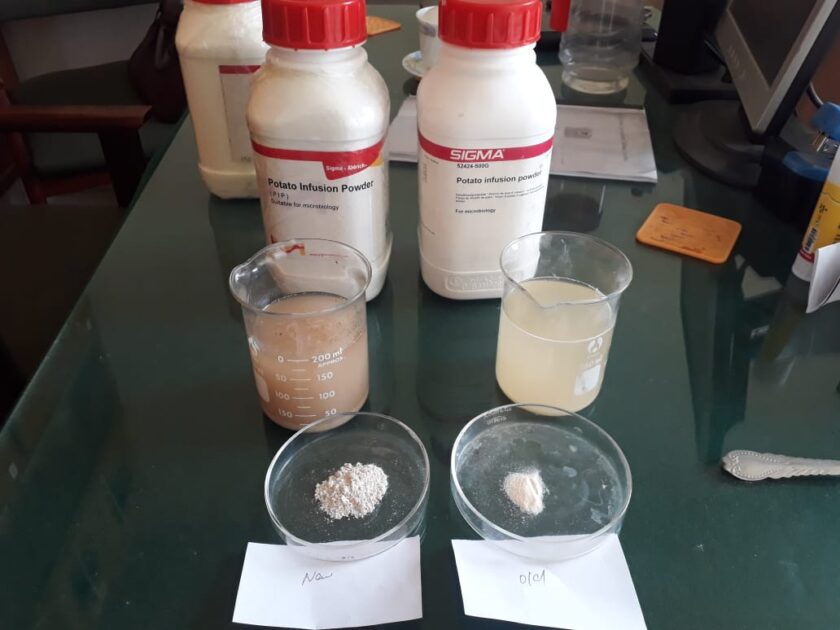

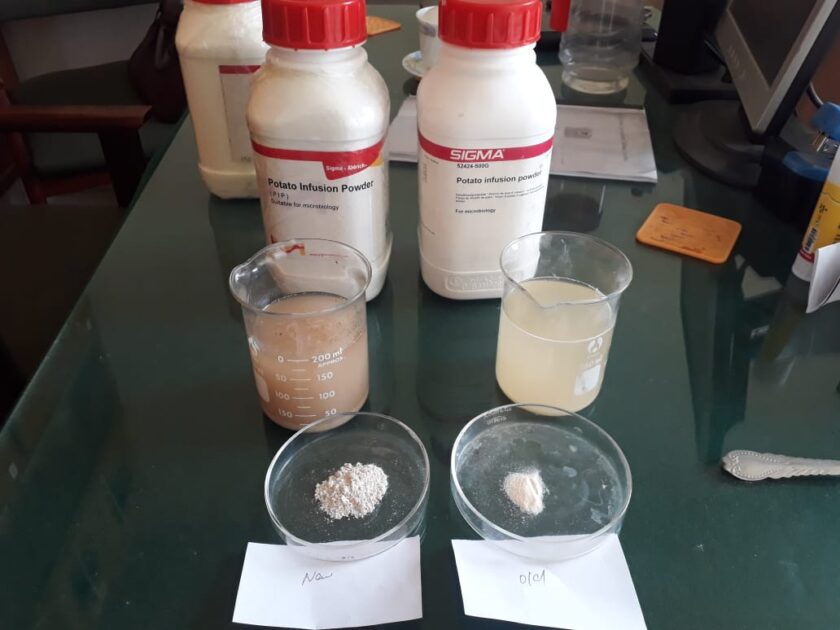

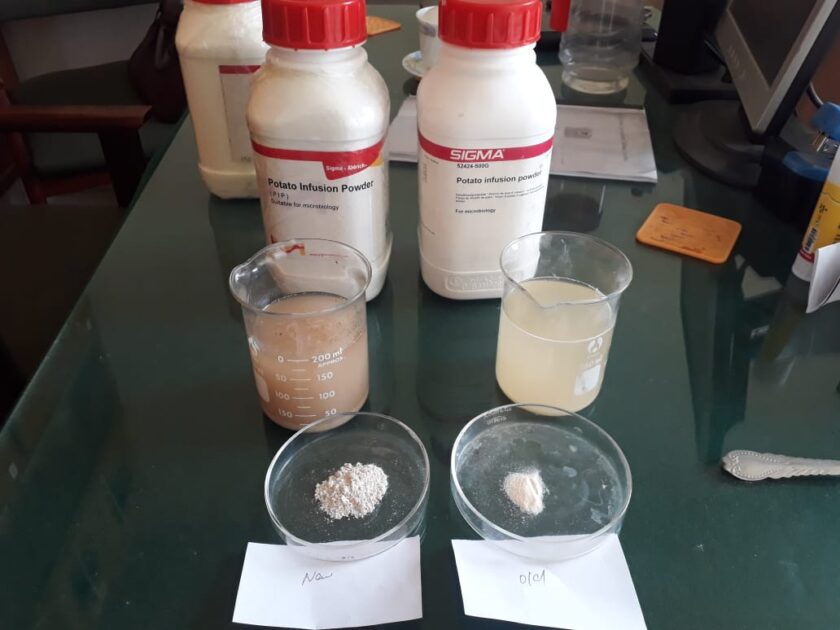

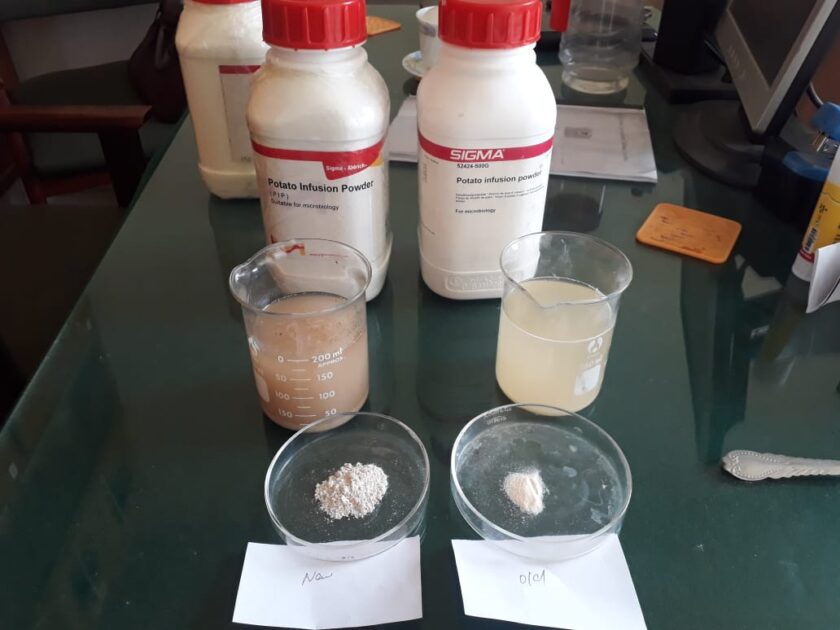

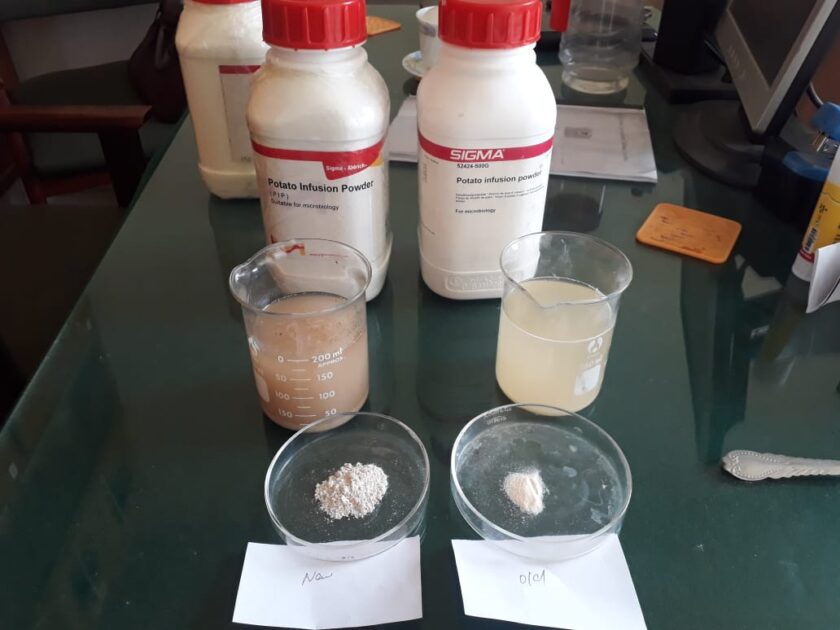

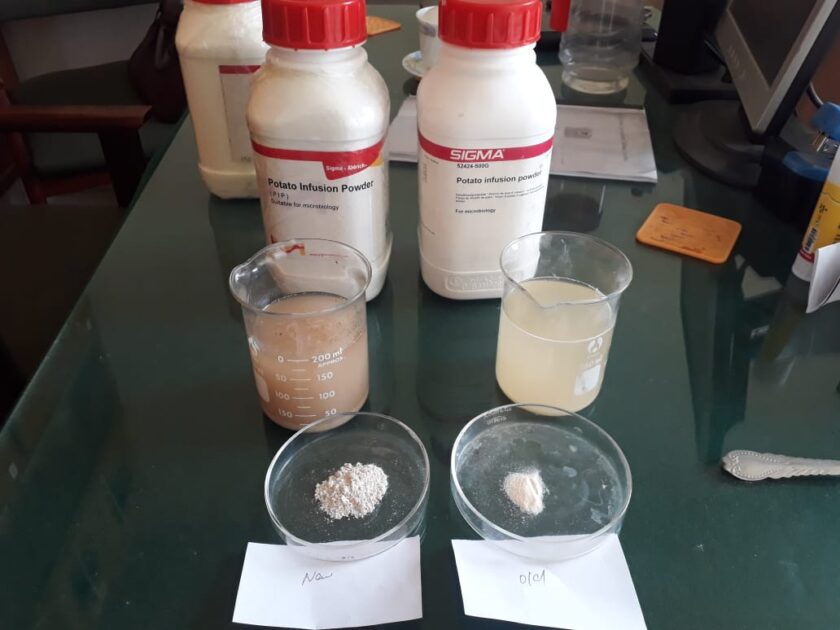

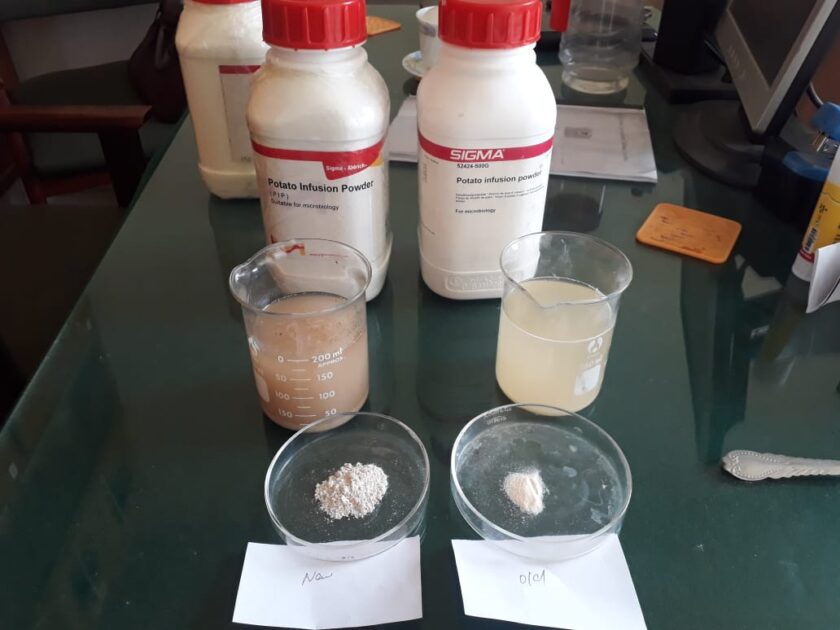

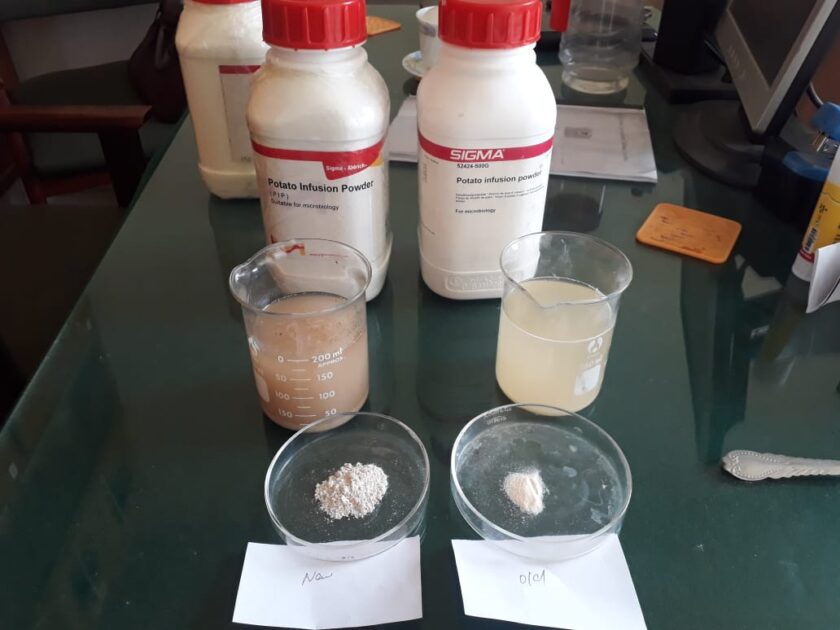

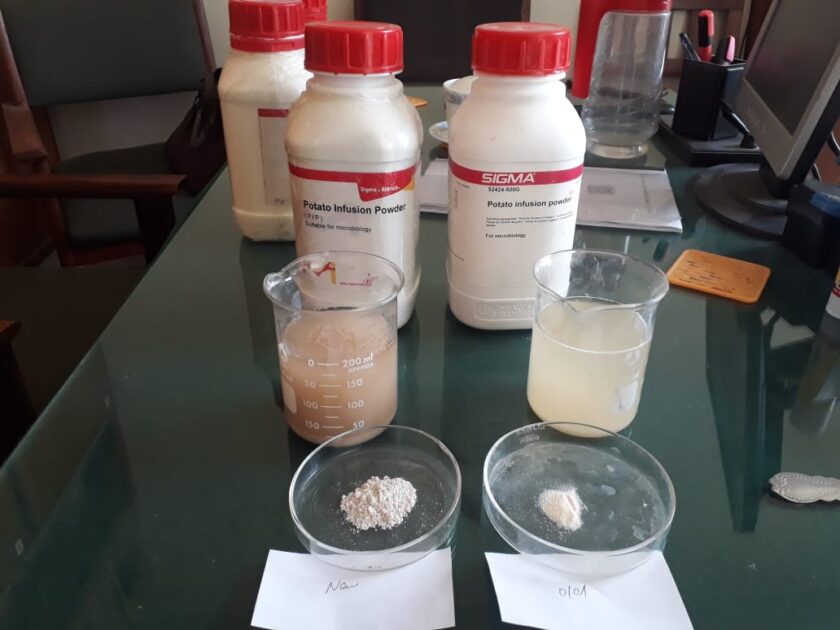

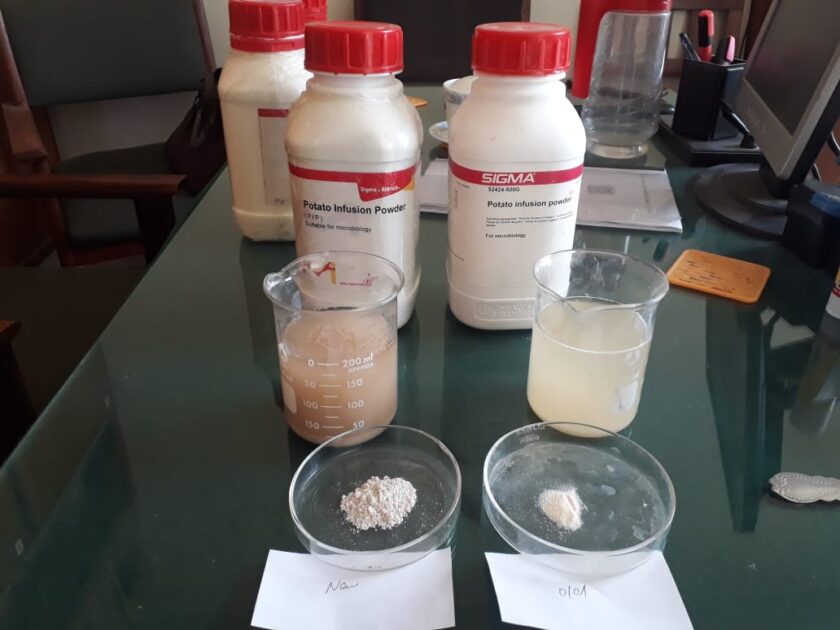

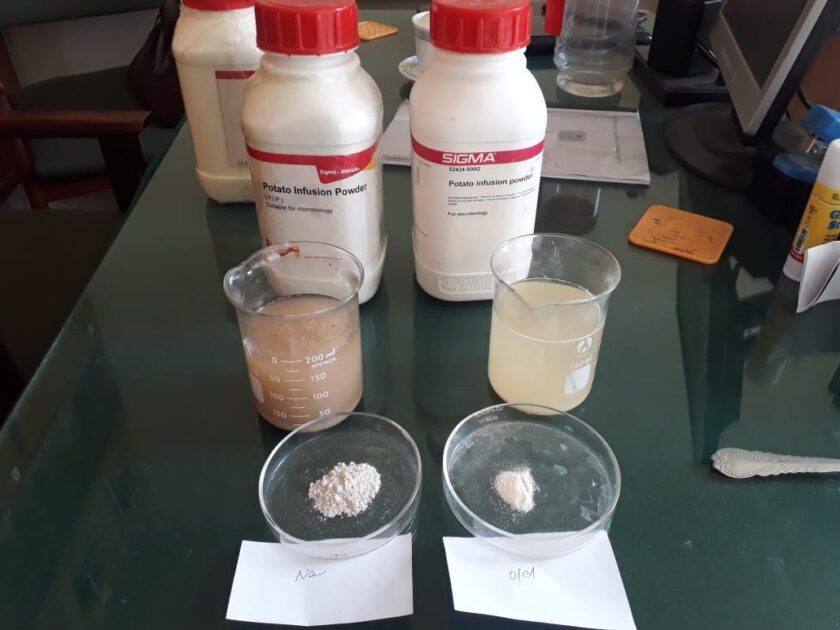

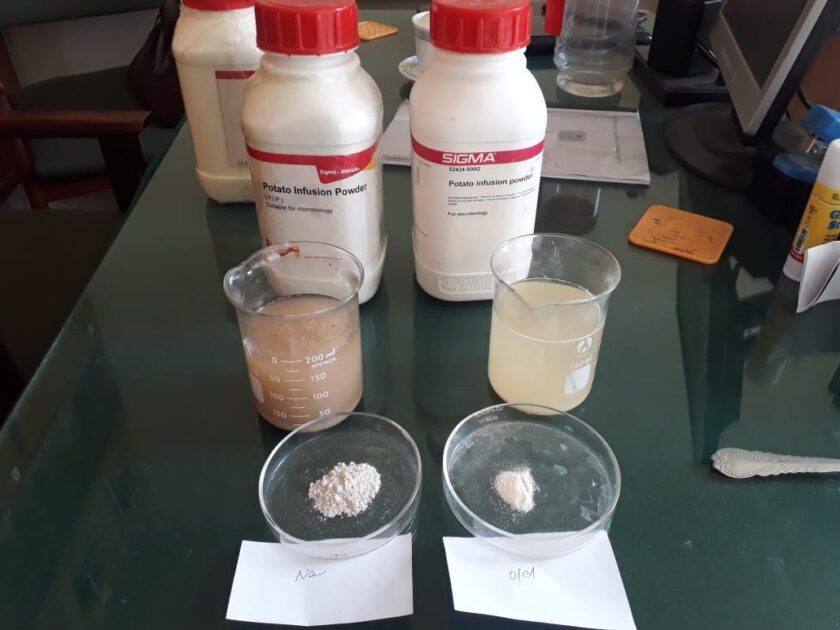

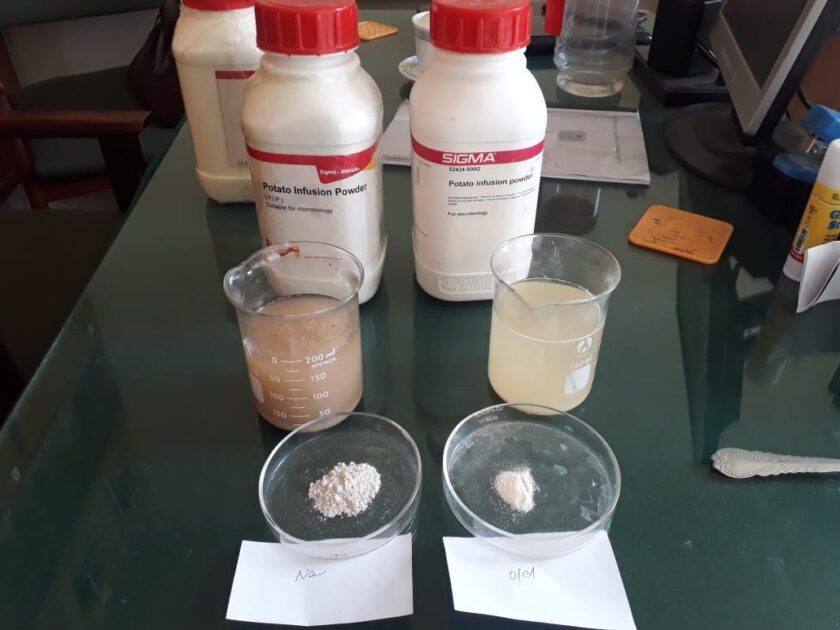

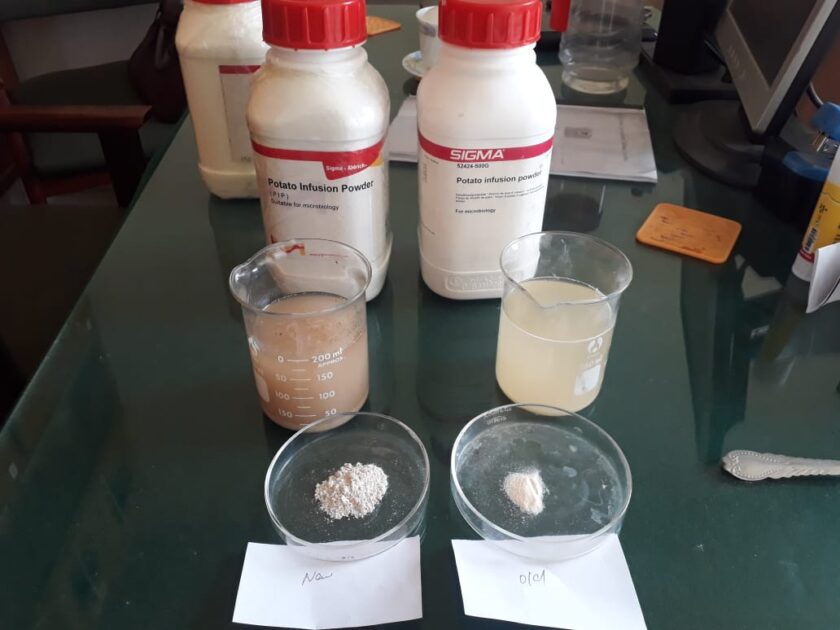

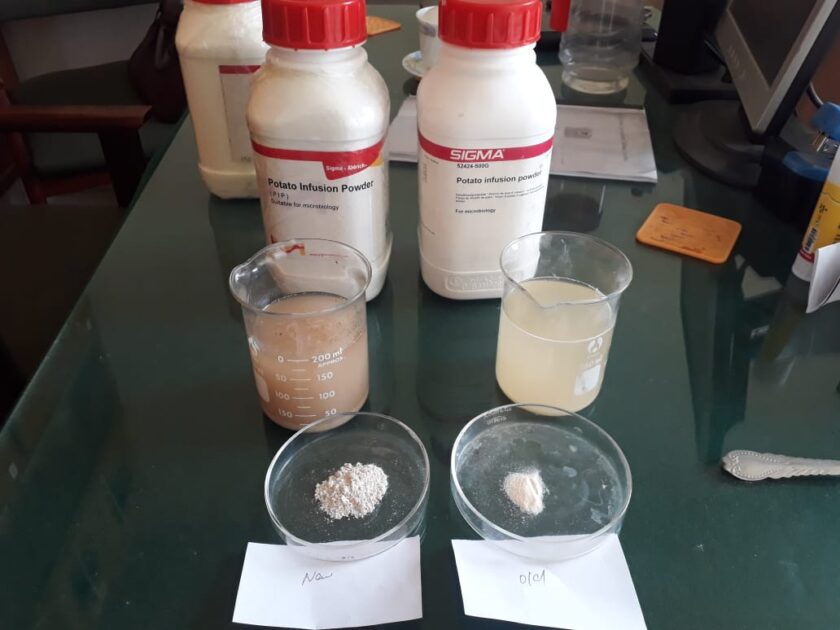

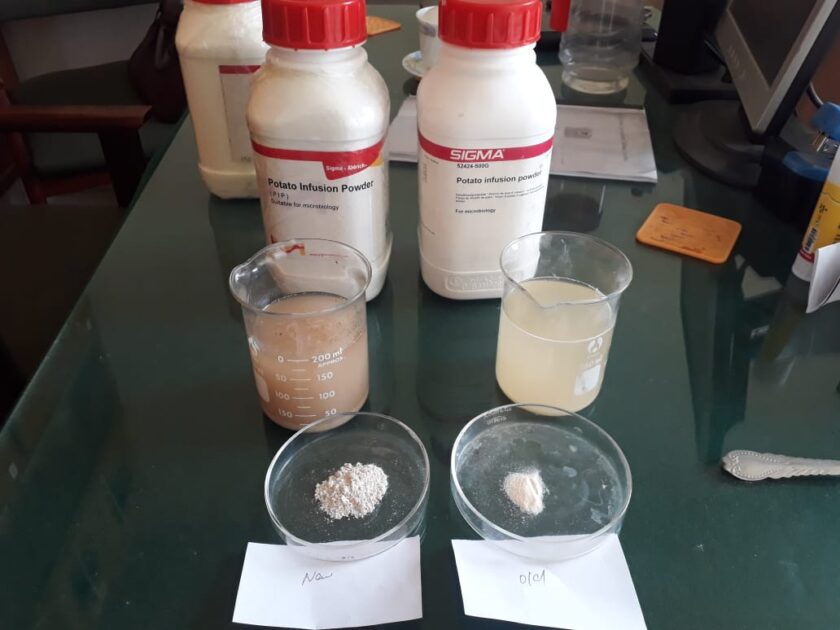

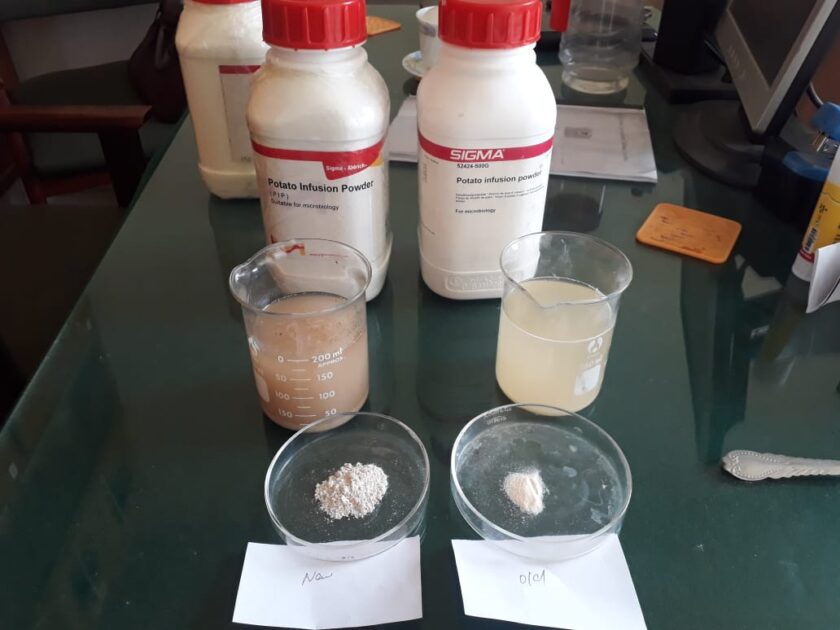

Let’s discuss shortly some main facts that might be the cause of PDA Color Variation. Potato Dextrose Agar (PDA) is a widely utilized culture medium in the field of microbiology, catering to the growth of various fungi and yeast species. However, users may encounter noticeable differences in color among different batches of PDA. While these variations are generally harmless, understanding the factors that contribute to such color differences becomes paramount to ensuring the medium’s quality and effectiveness for microbiological research.

Investigating the Causes of Variation in Media (Potato Dextrose Agar) Color

Ingredient Variation: Unraveling the Culprit

Even when sourced from the same company, minor variations in the formulation or sourcing of PDA ingredients can occur. The composition differences in raw materials might lead to varying colors between batches, impacting the overall appearance of the medium.

Storage Conditions: The Key Players

The storage conditions of PDA bottles play a pivotal role in bringing about color changes. Exposure to light, heat, or other environmental factors can cause degradation or oxidation of specific components, ultimately leading to alterations in color over time.

Keeping an Eye on Expiration Date

Checking the expiration date of PDA is crucial. An older PDA might undergo changes due to its age, resulting in discolouration and potential loss of effectiveness.

Air’s Influence: A Chemical Tale

Certain components of PDA are sensitive to air reactions. The prolonged exposure to oxygen can cause chemical changes, directly affecting the color of the medium.

Chemical Reactions: Disclosing the Color Play

The combination of ingredients may undergo chemical reactions, which could ultimately result in PDA Color Variation. Although these reactions usually do not affect the medium’s performance, they might significantly influence its appearance.

Adopting Batch Variability

when we discuss in the context of PDA Color Variation, So In large-scale production, slight batch-to-batch variability is a common occurrence. These minor differences in formulation or processing can significantly contribute to color variations among different batches of PDA.

It is important to note that slight color differences do not necessarily indicate a problem with the PDA medium. However, to ensure its suitability for microbiological work, performing a growth promotion test with standard organisms is recommended. This test will confirm whether the medium remains effective in supporting the growth of target microorganisms.

If you have big worries about the color differences in PDA bottles or any doubts about the medium’s quality, feel free to contact the manufacturer. They will give you more information & answer your questions.

Conclusion: Revealing Insight for Laboratories and Researchers

Understanding the various factors that contribute to PDA Color Variation (Potato Dextrose Agar) is crucial for laboratories and researchers working with fungal and yeast cultures. By being aware of these factors and taking appropriate steps to verify the medium’s performance, you can ensure reliable and consistent results in your microbiological experiments. Stay vigilant, and let the science of color guide you towards excellence in your microbial endeavours.

To read more about Potato dextrose agar

FAQs about Potato Dextrose Agar (PDA) Color Variation

Q1. Why does Potato Dextrose Agar (PDA) exhibit color differences among different batches?

A: PDA may show color variations due to ingredient variation, storage conditions, chemical reactions, air exposure, and batch variability. Minor differences in formulation or raw materials can impact the medium’s color.

Q2. Are color differences in PDA a cause for concern in microbiological work?

A: Not necessarily. Slight color differences typically do not affect the medium’s performance. However, to ensure its suitability, conducting a growth promotion test with standard organisms is recommended.

Q3. Can storage conditions affect the color of PDA?

A: Yes, storage conditions play a significant role in color changes. Exposure to light, heat, or environmental factors can lead to degradation or oxidation of certain components, resulting in alterations in color over time.

Q4. How can I verify the quality of PDA with noticeable color differences?

A: Conduct a growth promotion test using standard organisms to verify its quality. If you have concerns, don’t hesitate to contact the manufacturer for further information and clarification.

Q5. Is batch-to-batch variability common in PDA production?

A: Yes, in large-scale production, slight batch-to-batch variability is common. Minor differences in formulation or processing can contribute to color variations between different batches of PDA.